Mads and Ava of Sail Life are back, tackling another crucial repair on their 44 ft hurricane-damaged DIY catamaran, Spiffy. The immediate problem? Leaky, temporary plywood hatch covers that allowed a "massive amount of water" into the port forward cabin. This project, however, is more than just replacing covers; it’s a necessary test run for creating much bigger fiberglass components, such as the catamaran’s "eyebrows," later in the refit.

Designing and Machining the Mold

Mads took viewers through the meticulous process of designing a female mold using CAD, ultimately settling on a pointy-tip shape to test how heavier materials would handle complex angles. The female mold was constructed from three layers of 19 mm thick MDF. To address the alignment challenge for future tall molds, Mads tested using a round bar for a friction fit between the layers, noting the assembled mold felt "nice and solid" with "absolutely no flex or looseness."

After fixing thin edges with Bondo, Mads sanded the mold to 600 grit, applied two coats of wax, and then sprayed on three coats of PVA mold release. He noted a key learning point: he needs to become better at trusting the PVA and applying thinner coats to prevent runs that result in indentations in the finished gel coat.

The Laminating Test

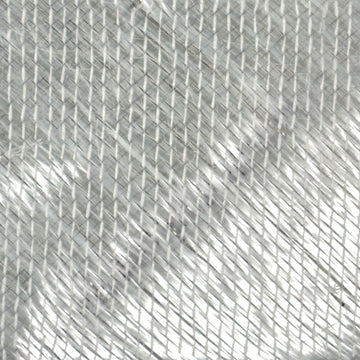

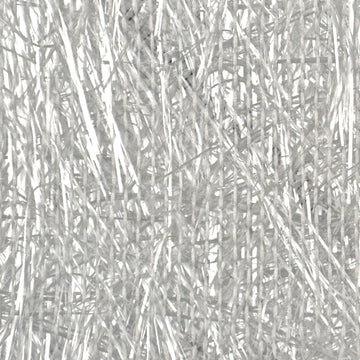

The goal was to test a heavy-duty laminating scheme that would be similar to the one needed for the eyebrows, involving gel coat, veil, chop strand, 1708, and 3mm core mat, a material Mads had never used before.

For the fabrication of the hatch, Mads first applied gelcoat in the mold. He then proceeded with the complex layup using various materials and polyester laminating resin. The final part pulled out of the mold with surprising ease, confirming the success of the 10° release angle built into the design. Mads learned several key lessons, including the difficulty of sanding inside corners compared to outside corners, and the realization that avoiding shallow angles could save many hours of CNC machining time.

TotalBoat Products in the Spiffy Refit

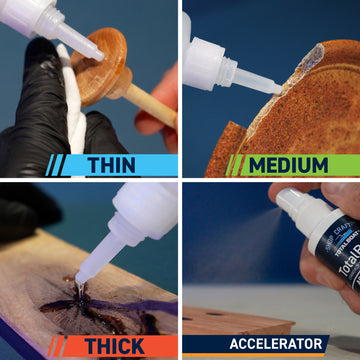

Mads continues to rely on high-quality materials throughout the massive refit of Spiffy:

-

TotalBoat High Performance Epoxy: In prior projects, Mads used High Performance Epoxy to prep MDF molds, ensuring a smooth, durable surface. He also successfully experimented with using High Performance Epoxy for vacuum infusion, finding its low viscosity when warmed made the process viable. For protecting temporary plywood floors inside the boat, he applied a single coat of High Performance Epoxy. For structural work on the keel, he used High Performance Epoxy for fiberglass layups.

-

TotalFair and TotalBilge: When rebuilding the catamaran’s keel, TotalFair Epoxy Fairing Compound was used to make necessary repairs. In the engine compartments, Mads utilized TotalBilge (a one-part epoxy-based paint) for a tough, protective finish on both the compartments and the battery shelves.

What's Next for Sail Life?

Next week, Mads is moving into production mode: making a second hatch, creating two deck rings (essential for making the hatches leak-free), and laying up the final clamshell covers. He is excited about the potential purchase of a property that would allow him to begin the big exterior projects and fully gut the interior of the catamaran.

Need to catch up on Sail Life’s total refit journey?

-

See Mads test the limits of resin in our article: Experimenting with Vacuum Infusion with Sail Life.

-

Check out how Mads used TotalBoat products to fix hidden damage in our post: Rebuilding the Keel of a 44ft Catamaran with Sail Life.