Halcyon Water-Based Marine Varnish

Regular price

$22.99-$134.99

Sale price

$22.99-$134.99

Unit price

per

Lust Rapid Recoat Marine Spar Varnish

Regular price

$31.99-$134.99

Sale price

$31.99-$134.99

Unit price

per

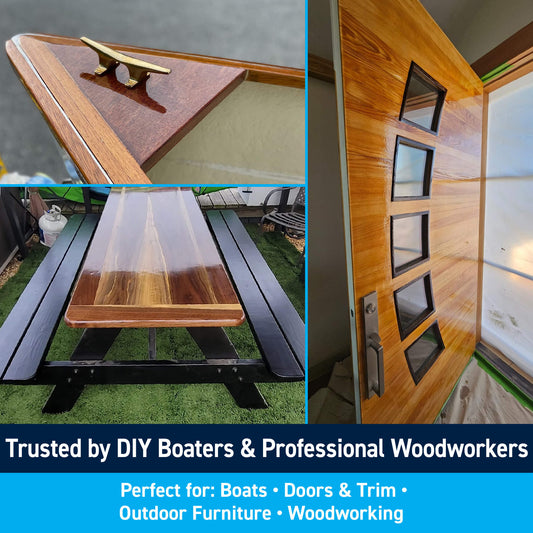

MARINE VARNISH

What is Varnish?

People use the word ‘varnish’ for just about any type of wood finish, but it’s actually a transparent coating containing an oil, a resin, and a solvent, designed to be applied to the surface of wood to protect it, and bring out the beauty of the grain. It’s used on all types of wood in all kinds of places – floors, furniture, cabinets, wooden boats, and many other indoor and outdoor wood surfaces.Varnish seals and protects wood, and makes it look good. It forms a protective film that prevents moisture, rot, and scratches from damaging wood, while enhancing the depth and beauty of the wood grain. For outdoor use, it also contains UV inhibitors to protect the finish – and the wood itself – from the sun’s punishing rays.

Different Types of Varnish

Manufacturers vary the type and proportion of drying oil, resin, and solvent to create a range of products, specifically for interior or exterior use. Modifying the components affects properties such as gloss, color tone, and flexibility (or brittleness) – which can also impact the price.There are lots of different types, but natural resin varnish (such as Tung oil), alkyd, and oil-modified polyurethane are a few of the most common.

The choices can be daunting, but for exterior surfaces, you’ll have better results if you choose a product with sufficient UV protection to match your local climate – especially if you own a boat or outdoor teak wood furniture. Changes in latitude should change your attitude; a boat in Miami needs more UV protection than a boat in Maine.

It’s also a good idea to use a marine-grade finish on the exterior surfaces of your home or on outdoor wood furniture – since it stands up to the elements at sea, it’ll be more than able to handle the weather outside your front door. If you’re applying it to interior surfaces, such as cabinets and furniture, you don’t need to pay more for expensive drying oils, UV additives, and superior flexibility.

Finishes can range from head-turning high-gloss to low-sheen satin to matte (flat), depending on the look you’re going for. When the desired finish is anything but high-gloss, we always recommend using high gloss for build coats, then 1-2 coats of the desired satin or matte finish. This will help to expand the color tones and natural richness of the wood.

Depending on the type you apply, the cured color can be clear (polyurethane varnish) all the way to a rich amber (spar varnish – the color is derived from the oil it contains). You can even tint it to create your own custom color, or stain the wood beforehand to achieve a certain tone.

Regular Varnish vs. Spar Varnish vs. Spar Urethane

What’s the difference? Regular varnish is typically used indoors because it won’t tolerate the harsh conditions that outdoor wood is exposed to, and the extreme expansion and contraction of the wood underneath. We’re talking big swings in temperature and humidity, plus damaging UV rays that will eventually cause a regular finish to fail.

Traditional spar varnish was used to protect the wooden spars that supported the sails on seafaring ships. It contains tung oil and specific resins that make it very durable, hard, and provide crucial protection from UV exposure. It also tolerates wood’s expansion and contraction caused by ambient weather and humidity changes. Spar urethane is a modern version, but contains urethane plastic as one of its resins instead of alkyd or phenolic resin, which provides excellent UV stability.

Varnish vs. Polyurethane

Both provide protective, durable finishes when cured. The differences lie in what they’re made of, what they’re used for, and what type of protection they give the wood. Varnish consists of oil, resin, solvent and additives, while polyurethane is an oil-based or water-based plastic resin.

Though both offer finishes ranging from flat (matte) to satin to high-gloss, varnish is more flexible than polyurethane, cures to a nice warm amber finish with greater depth (as opposed to a clear finish), and provides UV protection. Polyurethane products can offer a truly clear finish that doesn’t expand or change the color of the wood.

Because it’s better suited for outdoor use, varnish is ideal for boats, outdoor furniture and soft wood surfaces exposed to the elements. Polyurethane is generally more affordable, and recommended for interior wood furniture, desks, book cases, wood floors and other indoor, hard wood surfaces that are not as prone to direct UV exposure or the elements.

Varnish vs. Wood Oil

Varnish is a film-forming finish that sits on the surface of the wood as it hardens and cures. It comes in a range of finishes – from high gloss to matte (flat, no gloss). The more coats you apply, the more it enhances the beauty of the grain.

Wood oil is a natural-looking, penetrating finish that seeps into the wood fibers before it hardens and cures. When it’s wet it has an oily sheen, but dries to a matte finish. To retain the finish and moisture resistance, it needs to be reapplied over time. Some wood oils are safe for food contact, once cured, and are used on cutting boards. Other wood oils, such as teak oil, are used on teak boat decks.

While both of these finishes provide moisture protection, wood oil doesn’t prevent scratches and UV damage.

Varnish vs. Marine Wood Finishes

Synthetic marine wood finishes are faster and easier to apply, and don’t require tedious sanding between coats, which makes them ideal for brightwork. Like varnish, marine wood finishes are flexible when cured, can be used on all types of interior and exterior wood surfaces, and offer good UV protection.

As far as looks go, some marine wood finishes are tinted with synthetic iron oxide, which can give more of a pigmented look, rather than a natural, transparent amber finish. These tinted, synthetic finishes tend to be less transparent, and show greater opacity after a few coats have been applied, depending on the product.

Applying Varnish to Teak Wood

Teak is an oily wood that will turn gray when exposed to the elements. Some people prefer the gray, weathered look. Many don’t. Caring for teak on boat decks and outdoor furniture isn’t difficult, it just takes a little time and effort to clean and preserve teak to restore its natural golden tone.

Teak contains natural oils that prevent drying, so varnishing isn’t required to protect outdoor teak, but applying it does provide UV protection, showcases the wood grain, and helps retain the natural beauty and color.