We are excited to be back in the boat shop with the master of boat restoration, Andy Miller of the popular YouTube Channel, BoatworksToday. In today’s featured video, Andy takes us through a comprehensive demo of the best methods for overhead fiberglassing applications.

Fiberglass work is a crucial skill for any boat enthusiast or DIYer looking to perform repairs or modifications. When it comes to working on vertical or overhead surfaces, the challenges multiply, and the technique becomes even more critical. In today’s video, Andy will take us through this process. With a large sample board as his canvas, he showcases three distinct techniques, each with its own advantages and best use cases. Join us as we delve into the world of fiberglass craftsmanship and explore the methods presented in Andy's insightful video.

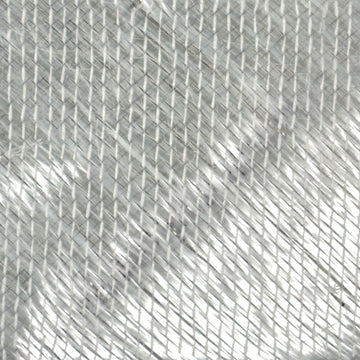

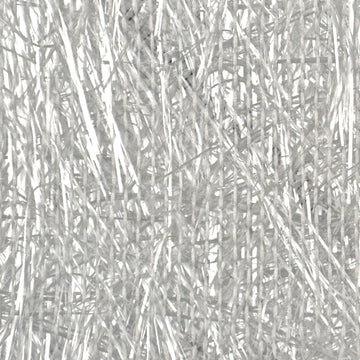

Andy begins by preparing the test board to ensure a clean and durable surface for the fiberglass applications. He starts with a layer of 1708 Biaxial Fiberglass Cloth, expertly wetting it out with Polyester Laminating Resin. Once cured, he applies a coat of Gelcoat in White, followed by sanding in down and wiping the surface with Dewaxer & Surface Prep. This careful preparation sets the stage for evaluating the different fiberglass techniques in an unbiased manner.

The first method showcased by Andy is the tried and true approach for vertical and overhead fiberglass applications. He applies the resin to the fiberglass cloth, but instead of fully saturating it, he leaves it wet but not dripping. Holding up the cloth against the vertical surface, he employs a roller to wet out the cloth, ensuring proper adhesion and consolidation. This technique is ideal for structural repairs and below the waterline applications, as it offers excellent strength and durability.

In the second method, Andy demonstrates a unique approach that involves rolling a thin layer of resin directly onto the surface. He waits until the resin starts to become tacky, reaching a point where a piece of paper towel can stick to it. At this stage, he applies the fiberglass cloth, allowing it to bond to the tacky resin layer. From there, he proceeds to wet out the cloth using additional resin. This method is versatile and can be used for both structural and cosmetic repairs, depending on the project's requirements.

The final technique presented by Andy involves using a spray adhesive on the surface before applying the fiberglass cloth. This method is particularly suitable for cosmetic repairs where a seamless, smooth finish is desired. The adhesive helps the cloth adhere to the surface and prevents it from sagging or slipping during the application of resin. While it may not provide the same level of structural integrity as the first method, it excels in achieving an aesthetically pleasing result.

With the three methods laid out, it's essential to consider the purpose of your fiberglass application when selecting the most suitable technique. If your project involves structural repairs or applications below the waterline, the first method, wetting out the cloth first, is the most reliable choice. On the other hand, if your focus is on cosmetic repairs, the spray adhesive technique (method 3) will help you achieve a seamless finish. The second method offers flexibility and can be adapted to either structural or cosmetic repairs, depending on the resin application.

The video provides an invaluable resource for anyone venturing into upside down/overhead fiberglass work. By presenting three distinct methods, he equips viewers with a comprehensive understanding of the techniques and their respective applications. Remember, proper surface preparation, choice of materials, and selecting the right method are key factors in achieving successful fiberglass applications. Whether you're repairing a boat, working on a home project, or simply honing your skills, Boatworks Today's video serves as a valuable guide for mastering fiberglass layup in vertical and overhead applications. Thanks for watching!

1 comment

You should model better safety awareness in your videos. It is irresponsible to be putting out “how tos” that disregard basic precautions. Particularly eye protection and in this case here, no respirator despite using a styrene based CSN neuro toxin resin.🤔☹️