BEAUTIFUL, UV-STABLE VARNISH ALTERNATIVE

EASY TO APPLY, NO SANDING BETWEEN COATS

PRESERVES INTERIOR AND EXTERIOR WOOD

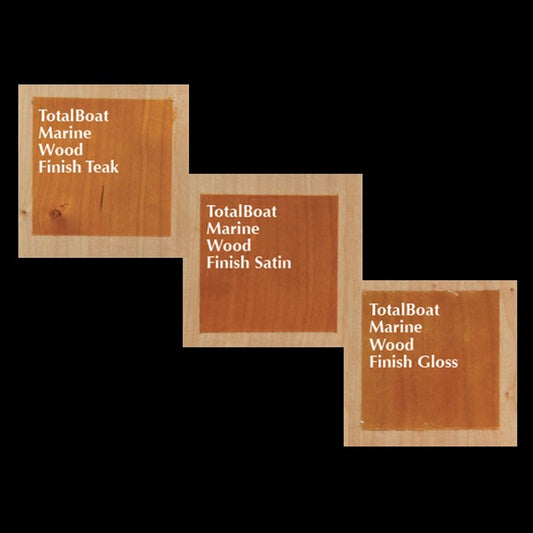

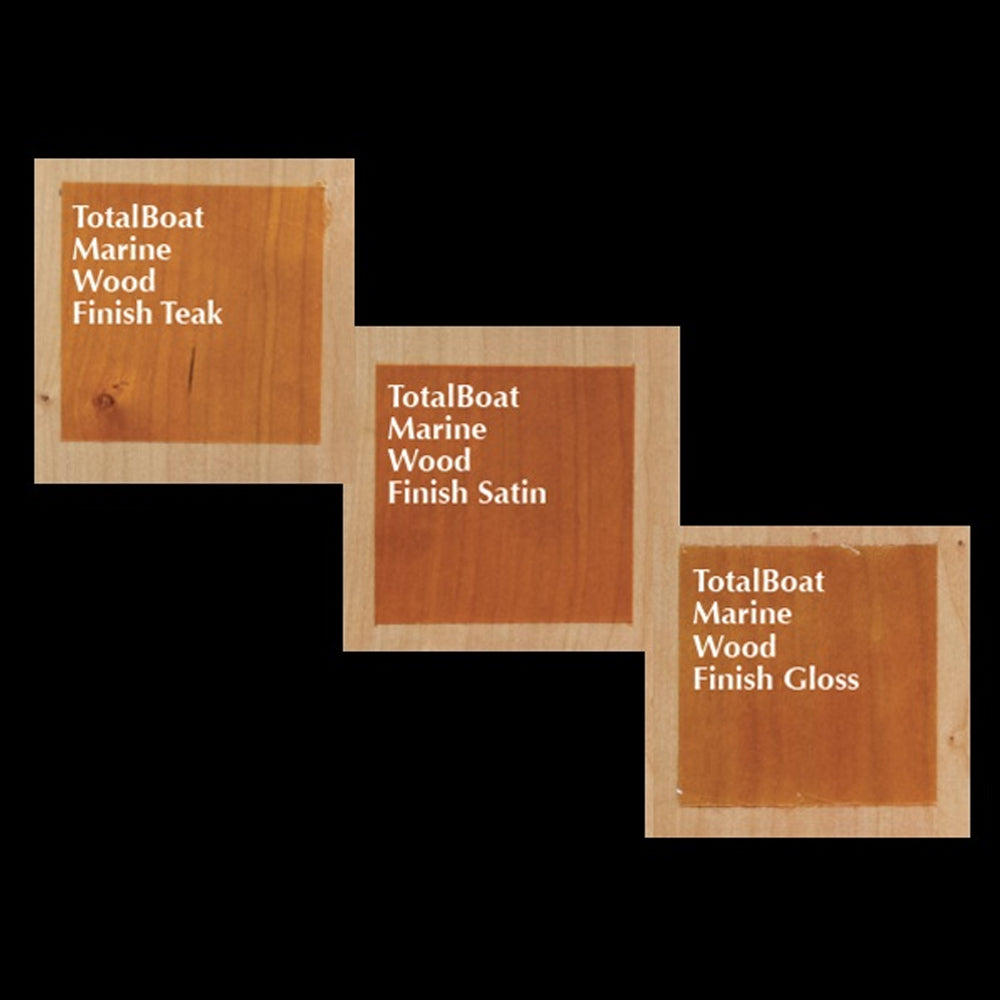

NATURAL TEAK, SATIN, AND GLOSS FINISHES

Marine Wood Finish

Marine Wood Finish

BEAUTIFUL, UV-STABLE VARNISH ALTERNATIVE

EASY TO APPLY, NO SANDING BETWEEN COATS

PRESERVES INTERIOR AND EXTERIOR WOOD

NATURAL TEAK, SATIN, AND GLOSS FINISHES

Couldn't load pickup availability

Get the beauty and UV protection of varnish, without the effort

The condition of your boat’s brightwork and other wood shouldn’t be a reflection on you, but we all know better. Traditional varnish is one way to go. An expensive, time-consuming, labor-intensive way to go that requires expensive, time-consuming, labor-intensive effort to maintain. What price beauty?

TotalBoat Marine Wood Finish has a high solids content that allows you to build coats like a varnish to beautify, seal, and protect interior and exterior wood surfaces. It brings out the beauty of the wood grain like varnish does, and it’s flexible to prevent cracking. It also contains substantial UV inhibitors to prevent fading and shrinkage like gloss varnish has. But here, the similarities end.

Marine Wood Finish is easier to apply than varnish, and much easier to maintain

TotalBoat Marine Wood Finish is not varnish. It penetrates teak and other marine woods deeply, more like a sealer, for exceptional protection. It’s also not as finicky to apply as varnish. In fact, it’s as easy and as forgiving as applying paint. Better yet, it doesn’t have to be sanded between coats like paint and varnish.

Better UV protection, better value

Our Marine Wood Finish has a better UV package than other non-varnish wood finishes. And our UV protection extends to all of our finishes – even Satin – which in the traditional varnish world is usually used below decks and doesn’t contain the same amount of UV protection. All of our Marine Wood Finish products are fortified with UV inhibitors and can all be used on interior and exterior wood.

Natural Teak, Satin, and Gloss finishes offer versatile results

These finishes can be used alone or together, depending on the wood you’re coating and the look you’re aiming for. For example, on teak brightwork, you could use the Natural Teak finish to give the wood depth, then overcoat with Gloss finish to make it truly live up to its name. Or you could simply use Gloss on brightwork, without applying the Natural Teak finish first. And the Natural Teak finish isn’t just for teak, it’s for any wood you might want to change the color of a little bit toward the darker side. The Gloss can also be applied over the Satin finish for higher gloss results. These finishes can also be applied over epoxy on brightwork for UV protection and a very unique look. When you’re done, you’ll get the beauty and protection of varnish, and you’ll have spent a lot less time, money, and effort to get it.

Marine Wood Finish Details

- Protective wood treatment for exterior use above the waterline and on all interior surfaces.

- Softer, more flexible finish provides durable protection.

- Easier to apply and maintain than varnish, with even distribution.

- No tedious sanding between coats.

- Apply a finish coat of Gloss over Natural Teak or Satin to create a varnished appearance, without the work.

- Size: Available in Quart and 2-Quart sizes

- 2-Quart kit includes brush, stir sticks, and cups.

FREQUENTLY BOUGHT TOGETHER

TECHNICAL DATA

- Substrates: Bare wood; wood sealed with epoxy

- Application Temperature/RH: 50-95°F, relative humidity 0-90%

- Application Method: Brush or Roll

- Application Film Thickness: 1-2 mils dry @ 3 mils wet

- Number of Coats: 2-3 (one seal coat followed by at least two more coats). Apply additional coats as needed for depth and enhanced appearance.

- Dry Time to Touch: 8 hours @ 90ºF, 12 hours @ 70ºF, 18 hours @ 50ºF

- Minimum Overcoat Time: 16 hours @ 90ºF, 24 hours @ 70ºF, 36 hours @ 50ºF

- Maximum Overcoat Time Without Sanding: 72 hours

- Color/Finish: Natural Teak (teak color tone, satin), Satin (wood color tone, satin), Gloss (clear, gloss)

- Coverage (@ 3 mils wet): 80-100 square feet per quart

- UV Stable: Yes

- Food Safe/Food Contact Safe (Once Cured): No

- Thinner: TotalBoat Special Brushing Thinner 100

- Surface Prep Solvent: TotalBoat Dewaxer & Surface Prep or TotalBoat Special Brushing Thinner 100 or TotalBoat Spray Thinner 101 or denatured alcohol

- Cleanup Solvent: TotalBoat Dewaxer & Surface Prep or TotalBoat Special Brushing Thinner 100 or TotalBoat Spray Thinner 101

-

Marine Wood Finish

- Best for:

- Substrates:

- Color/finishes available:

- Interior or exterior use?

- Film forming or oil finish?

- Application methods:

- Number of coats:

- Primer required?

- Application temperature/RH:

- Cure times:

- Food safe, once cured?

- Units of measure:

- THIS ITEM

-

Marine Wood Finish

- Best for: Sealing, protecting and preserving wood.

- Substrates: Bare wood; wood sealed with epoxy

- Color/finishes available: Natural Teak (teak color tone, satin), Satin (wood color tone, satin), Gloss (clear, gloss)

- Interior or exterior use? Interior and exterior

- Film forming or oil finish? Film forming

- Application methods: Brush, Roll

- Number of coats: 2-3 coats (minimum)

- Primer required? No

- Application temperature/RH: 50-95°F; 0-90% RH

-

Cure times:

• Dry to touch: 8 hrs @ 90°F; 12 hrs @ 70°F; 18 hrs @ 50°F

• Dry to overcoat: 16 hrs @ 90°F; 24 hrs @ 70°F; 36 hrs @ 50°F - Food safe, once cured? No

- Units of measure: Quart, 2 Quarts

-

Wood Honey Food Safe Wood Finish

- Protective, food-safe wood finish, friction polish for wood

- Wood

- Yellow color, low-sheen finish

- Interior

- Oil

- Rag, Scotch-Brite pad (ultra-fine ONLY)

- 2 (bare wood); 1-2 (maintenance)

- No

- 50-95°F; 0-90% RH

- 5-7 days for full use

- Yes

- 8 fl oz, 16 fl oz

-

Danish Teak Sealer

- Penetrating and sealing wood to protect against mold and mildew. Minimizes graying and staining.

- Teak; oily hardwoods

- Light golden color

- Interior or exterior

- Oil

- Brush or Clean Rag

- 2 (bare wood); 1-2 (maintenance)

- No

- 40-95°F; 0-90% RH

- Allow to dry for 8-12 hours between coats.

- No

- Quart, Gallon

YOU MAY ALSO LIKE

FREQUENTLY ASKED QUESTIONS

-

Is TotalBoat Marine Wood Finish considered a varnish?

Marine Wood finish is an alternative to varnish. Its formula is different from urethane varnishes. It is intended to provide the attractive appearance of traditional spar varnish, but is much easier to apply. For instance, only 2 to 3 coats are necessary, with no sanding between coats. Wood Finish is a more flexible coating, allowing wood to breathe without causing finish blisters. It is a lower maintenance finish, as it doesn’t frequent care, and it penetrates wood better. -

Can it be applied over epoxy for a final finish?

Yes, Marine Wood Finish may be applied over epoxy, but the cured epoxy has to be properly prepared. You have to remove any potential amine blush with soap and water, rinse completely, dry completely, sand lightly, use a clean lint-free rag dampened with denatured alcohol to remove sanding residue, then allow the surface to dry completely, before applying. -

How many coats of Marine Wood Finish should I apply?

We recommend two to three coats for appearance and durability. You may apply additional coats as needed for depth and enhanced appearance. -

How long does it take to completely dry?

Since the dry time is dependent on the temperature, the time it takes to fully dry varies. The dry time to touch is between 8 hours to 18 hours. The dry time to overcoat can take anywhere between 16 hours to 36 hours. -

Does the wood finish dry clear or does it carry a color?

Marine Wood Finish is available in three finishes: Gloss yields a rich, warm finish and may be applied as a topcoat over the other finishes to add gloss. Natural Teak is designed to enhance the beauty of teak wood, and has a golden hue. Satin creates a classic low-sheen dark amber finish.