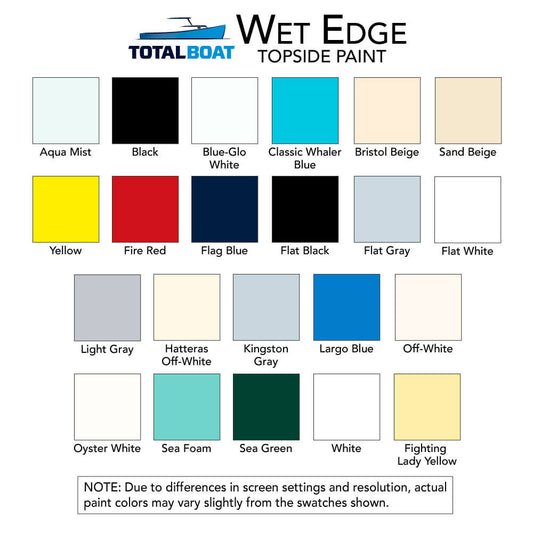

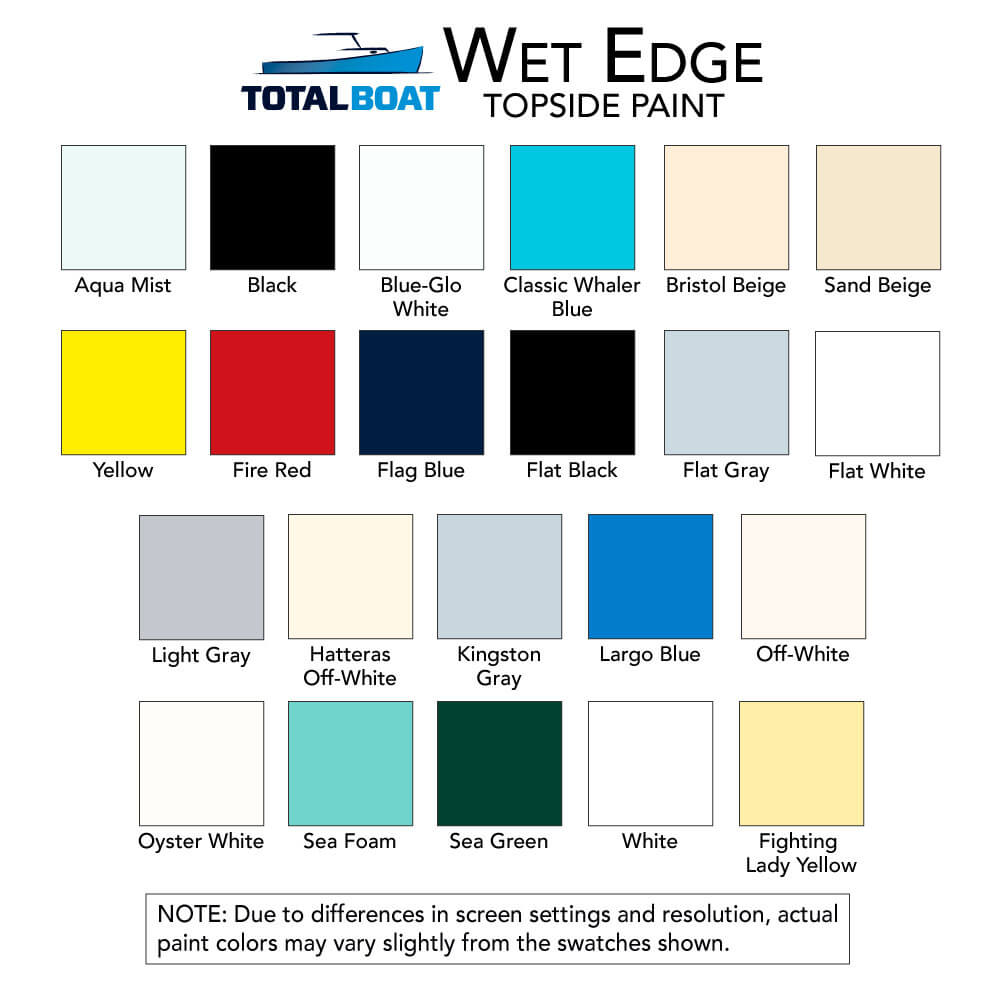

22 POPULAR COLORS

High-gloss and flat finishes in quarts and gallons.EASY TO APPLY

Apply by brushing, rolling & tipping, or spraying.LONG-LASTING FINISH

UV-stable, flexible finish has great color retention and won't chip, fade, or peel.CUSTOMIZE YOUR COLOR

Mix any of the Wet Edge colors to create your own.Wet Edge Topside Paint

Wet Edge Topside Paint

22 POPULAR COLORS

High-gloss and flat finishes in quarts and gallons.EASY TO APPLY

Apply by brushing, rolling & tipping, or spraying.LONG-LASTING FINISH

UV-stable, flexible finish has great color retention and won't chip, fade, or peel.CUSTOMIZE YOUR COLOR

Mix any of the Wet Edge colors to create your own.Couldn't load pickup availability

Get glossy, professional-looking results without spraying

Wet Edge was created so anyone could easily paint their boat’s topsides with pride and not pay a premium to do it. Of course, you can spray it on if you want to, but simple rolling and tipping produce praiseworthy results. Just remember always to brush from the wet edge into new paint, then leave it alone and it’ll lay down flat, smooth, and glossy. Be careful you don’t get a big head from all the compliments. If you need to prime first, our high-solids TotalBoat Topside Primer was created expressly for use under Wet Edge.

Lay it on thin

To get Wet Edge to cure to a rock-hard, super shiny finish, you have to think thin. Coats, that is. It’s loaded with solids so you don’t need to lay it on thick to get better coverage. You wouldn’t want to either, because it won’t dry as fast as it should. For best color and finish, we recommend 2-3 thin coats.

Very tough and very flexible

Wet Edge topside paint adheres to fiberglass and wood like wet on water, and expands and contracts effortlessly with your ever-shifting hull. Other one-part topside paints can lift, peel, or crack under this type of pressure.

Choose from 22 UV-stable colors or create your own

Consistency and UV stability are hallmarks of the available Wet Edge boat paint colors. From serene to bold and brilliant, these colors will always look as good as the day they were laid down. If you want to make your own color, just mix any of the existing Wet Edge boat paint colors.

Wet Edge Paint Details

- Beautiful, shiny, long-lasting polyurethane marine topside paint with excellent resistance to weather, chemicals, and abrasion.

- Unique formula allows hulls to expand & contract without finish lifting or cracking.

- Brush or spray above the waterline on wood, fiberglass, and previously painted surfaces in good condition.

- Compatible with flattening agents and non-skid additives.

- Quart Colors: Aqua Mist, Black, Blue-Glo White, Classic Whaler Blue, Bristol Beige, Sand Beige, Fighting Lady Yellow, Fire Red, Flag Blue, Flat Gray, Flat White, Hatteras Off-White, Light Gray, Kingston Gray, Largo Blue, Flat Black, Off-White, Oyster White, Sea Foam, Sea Green, White, Yellow

- Gallon Colors: Black, Aqua Mist, Blue-Glo White, Classic Whaler Blue, Bristol Beige, Sand Beige, Fire Red, Flag Blue, Hatteras Off-White, Oyster White, Light Gray, Kingston Gray, Largo Blue, Off-White, Sea Green, White, Yellow, Fighting Lady Yellow, Sea Foam, Flat White, Flat Black, Flat Gray

Frequently Bought Together

SEE HOW EASY IT IS TO APPLY WET EDGE

SEE HOW EASY IT IS TO APPLY WET EDGE

TECHNICAL DATA

- Application Method: Brush, Roll, or Spray

- Recommended roller: We recommend a solvent-safe 1/8" foam roller, designed for leaving glossy surfaces without any stipple or lint. This includes products such as ArroWorthy Mighty Mini rollers, or foam rollers that fit on regular paint roller frames.

- Do not apply with nap rollers. Nap rollers leave small hairs, as well as a stippled effect in the paint that will stand out once it cures, and will generally lay down too much paint for a proper cure.

- Application Film Thickness: 1-2 mils dry @ 3 mils wet

- Coverage (@ 3 mils WFT): 40-50 sq ft/pint, 80-100 sq ft/quart, 350-400 sq ft/gallon

- Number of Coats: 2-3 coats (minimum)

- Application Temperature/RH: 50-90°F, less than 85-90% RH

- Tack-Free Time: 1.5 hours @ 90°F, 3 hours @ 70°F, or 6 hours @ 50°F

- Minimum Overcoat Time: 8 hours @ 90°F, 12 hours @ 70°F, 16 hours @ 50°F

- Not recommended for steel without proper preparation, or aluminum unless properly etched and primed

- Not designed for continuous submersion on boat bottoms that remain in the water longer than 72 hours

- Components: One

- Finish sheen/gloss: High gloss (standard) (85-90°); Flattened (5-10°)

- UV stable: Yes

- Primer: TotalBoat Topside Primer (NOTE: Wet Edge can also be applied over TotalBoat epoxy primer systems, including TotalProtect, 2-Part Epoxy Primers, and Aluminum Boat Barrier Coat. See technical data sheet for details.)

- Thinning: Brush/roll - TotalBoat Special Brushing Thinner 100, 5-10%; Spray - TotalBoat Spray Thinner 101, 10-20%

- Surface prep solvent: TotalBoat Special Brushing Thinner 100 or TotalBoat Spray Thinner 101 or TotalBoat Dewaxer & Surface Prep

- Cleanup solvent: TotalBoat Special Brushing Thinner 100 or TotalBoat Spray Thinner 101 or TotalBoat Dewaxer & Surface Prep

-

Wet Edge Topside Paint

- Best for:

- Finish:

- Interior/Exterior?

- Primer:

- Thinner:

- Application methods:

- Application temperature & humidity:

- Number of coats:

- Cleanup:

- Coverage:

- UV Resistant?

- THIS ITEM

-

Wet Edge Topside Paint

- Best for: Painting wood and fiberglass boat hulls above the waterline

- Finish: High gloss (all colors); Flat (black, white, and gray only)

- Interior/Exterior? Interior and exterior (above the waterline only)

- Primer: TotalBoat Topside Primer (NOTE: Wet Edge can also be applied over TotalBoat epoxy primer systems, including TotalProtect, 2-Part Epoxy Primers, and Aluminum Boat Barrier Coat. See technical data sheet for details.)

- Thinner: TotalBoat Special Brushing Thinner 100 (brush/roll) or TotalBoat Spray Thinner 101 (spray)

- Application methods: Brush, roll and tip, or spray

- Application temperature & humidity: 50-90°F; humidity 0-90%

- Number of coats: 2-3 (minimum); between coats, sand lightly with 220-320-grit sandpaper

- Cleanup: TotalBoat Special Brushing Thinner 100 or TotalBoat Spray Thinner 101 or TotalBoat Dewaxer & Surface Prep

- Coverage: 350-400 sq. ft. per gallon (approximately 80-100 sq. ft. per quart)

- UV Resistant? Yes

-

TotalTread Non-Skid Marine Deck Paint

- Provides a non-slip surface on decks, docks, ramps, steps, cabin soles & other fibergalss and wood topside surfaces.

- Flat, gritty

- Exterior (above the waterline only)

- TotalBoat Topside Primer (wood and previously painted surfaces; not needed on properly prepared fiberglass), TotalBoat 2-Part Epoxy Primer (Metals), TotalBoat TotalProtect Barrier Coat (Fiberglass/Metals), TotalBoat Aluminum Boat Barrier Coat (Metals)

- Brushing/Rolling: TotalBoat Special Brushing Thinner 100, 5-10%, if needed; Spraying: TotalBoat Spray Thinner 101, 10-20%, if needed

- Brush, roll, or spray

- 50-90°F; humidity 0-90%

- Two; between coats, sand lightly with 220-grit sandpaper

- TotalBoat Special Brushing Thinner 100 or TotalBoat Spray Thinner 101 or TotalBoat Dewaxer & Surface Prep

- 250-300 sq. ft. per gallon

- Yes

-

TotalBilge Epoxy Bilge Paint

- Painting bilges, bulkheads, lazarettes and locker areas

- High gloss

- Interior only

- TotalBoat TotalProtect — only mandatory on metals, but may be used on properly prepared wood or fiberglass, if desired.

- Brushing/Rolling: If needed, thin 5-10% with TotalBoat Special Brushing Thinner 100; Spraying: TotalBoat Spray Thinner 101, 10-20%

- Brush, roll, or spray

- 50-95°F; humidity 0-90%

- 1-2; between coats, sand lightly with 220-320-grit sandpaper

- TotalBoat Special Brushing Thinner 100 or TotalBoat Spray Thinner 101 or TotalBoat Dewaxer & Surface Prep

- 250-300 sq. ft. per gallon

- No

Watch More Videos

-

Wooden Boat Build // Part 12: Painting the Boat // Roll & Tip Method

-

How to Roll and Tip Paint on Your Boat's Topsides

-

Boston Whaler Crazing Repair

-

How to Reinforce a Weak Boat Deck - Boatworks Today DIY Tips

-

TotalBoat: Do it yourself, but not on your own | Paint

GET GLOSSY, PROFESSIONAL-LOOKING RESULTS WITHOUT SPRAYING

YOU MAY ALSO LIKE

FREQUENTLY ASKED QUESTIONS

-

What can Wet Edge be used on?

This marine topside boat paint can be used on fiberglass, wood, or previously painted surfaces above the waterline. -

Do you need to prime before applying Wet Edge?

For the best results, you should prime using TotalBoat Topside Primer. Keep in mind, Wet Edge topside boat paint can also be applied over TotalBoat epoxy primer systems, including TotalProtect, 2-Part Epoxy Primers, and Aluminum Boat Barrier Coat. -

How do I apply this paint?

It’s best to use the ‘roll and tip’ method with a brush and roller. If you are applying the paint with a roller, we recommend using a solvent safe ⅛" foam roller, designed to leave glossy surfaces without any stipple or lint. If you are applying it with a brush, we suggest using a natural bristle or badger hair brush. You should not apply the Wet Edge Topside Paint with a nap roller because they leave small hairs, and will generally lay down too much paint for a proper cure. Wet Edge can also be sprayed. -

How many coats should I apply?

For the best color appearance and finish durability, we recommend two to three thin coats. -

How long should I wait before applying another coat?

We recommend 24 hours between coats. -

How long does it take for polyurethane marine topside paint to fully dry?

The dry time to touch is 1.5 hours to 6 hours, depending on the temperature. The dry time to overcoat is also dependent on the temperature. It can take anywhere between 8 hours to 16 hours before it’s fully cured. Be sure to apply thin coats. Applying Wet Edge too thick may cause problems with drying.