Bob Emser from The Art of Boat Building introduces us to a new boat build. He has been given the pleasure to build the 9’ tender for her mother ship, Arabella. In a collaboration with fellow YouTuber, Steve Denette, of channel Acorn To Arabella, Bob will redesign a William Atkins sailing dinghy. And in today’s video, Bob shows how to make and fit the custom bulkheads!

Acorn to Arabella is a wooden sailboat building project taking place in Granby, Massachusetts. Steve Denette started as an amateur boat builder, building a 38’ wooden boat in his backyard from the ground up. Many years ago, Steve had purchased his first wooden boat, Victoria. He got her knowing she was going to be a parts boat but it was still the first boat they ever owned, so it is bittersweet for them to take her apart and keep her legacy alive in these new builds. Bob visited the Acorn crew over the summer to pick up the usable material salvaged from Victoria that will soon become Arabella’s tender.

Bob begins working on the two bulkheads that will hold the center seat and the daggerboard trunk. After picking out the wood from his planking stock, he preps the boards, glues them together and cuts the daggerboard trunk sides down to 12”x12”. He then uses TotalFair Epoxy Fairing Compound to fill any of the voids or holes that had been left in the planks. Once this process is complete and all the panels ready, Bob needs to get the bulkheads placed inside the boat and get them fitted so he can cut out the curve.

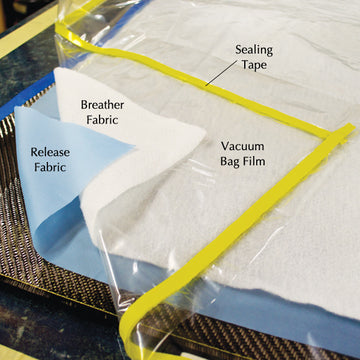

Next, Bob applies epoxy to the inside of the daggerboard trunk as well as the inside of the bulkheads that form the center seat inside the daggerboard trunks are also going to get a layer of 6 oz fiberglass cloth. This will give them some added reinforcement and abrasion resistance. Bob also uses Peel Ply Release Fabric for the first time. This will ensure a smooth surface and help remove any amine blush. See what he learns about its application with epoxy resin. Next, he temporarily clamps everything together and dry fits the bulkheads in place.

That concludes this week's episode. Be sure to subscribe to The Art of Boat Building and Acorn to Arabella channels to follow both boat building journeys. Videos and information about the tender’s build will be presented on both channels. Thanks for watching, and as Bob always says, “Remember, if you’re going to make it… make it beautiful!”

3 comments

Looking great

Nice. Only needs about $50K of machinery and 30 years of experience to make a perfect fit!!

No out feed on table saw. ??? I couldn’t live like that.