Rodak Garage is a labor of love, passion, and creativity, founded by Dave Rodak in 2021 with the support of his wife, Donielle. Based in Rochester, New York, Dave turned his frustration with the lack of quality wood shift knobs for his 1984 Toyota Corolla AE86 into a thriving business that specializes in handcrafted shift knobs. From his garage workshop, Dave meticulously hand-turns each piece on a wood lathe, creating unique, one-of-a-kind designs that reflect his dedication to quality and craftsmanship.

What began as a personal project to create the perfect shift knob for his own car has blossomed into a full-fledged brand that offers a diverse range of wood and resin knobs, as well as custom car-themed accessories. Whether it’s a classic wood knob or an eye-catching galaxy resin design, each piece is made with the utmost attention to detail, ensuring that no two are exactly alike. For Dave, it's not just about making a product; it's about creating something special for car enthusiasts who appreciate the artistry and individuality that goes into every piece.

Rodak Garage’s mission is simple: to craft the best handmade shift knobs and automotive décor that stand out in a world of mass-produced parts. Dave’s perfectionism and passion for the car scene drive him to constantly innovate and expand his offerings, from key hooks to reusable air fresheners and ornaments. With a commitment to excellence and a deep appreciation for his supporters, Dave continues to push the boundaries of what’s possible, one handcrafted shift knob at a time.

Can you tell us a little bit about how Rodak Garage started and what inspired you to specialize in shift knobs?

Rodak Garage started when I was looking for a knob for my old Corolla. I couldn't find anything that really jumped out at me, and being who I am, I said I could make one myself. 6 months in from trying to make one knob, I left my full-time job and made Rodak Garage full-time. I started with just wood knobs and then decided to try epoxy. I tried a lot of different brands of epoxy before TotalBoat and there was a LOT of trial and error.

What does your typical workflow look like when creating a custom shift knob from start to finish?

To be completely honest, there isn't one.

How do you source the different types of wood and epoxy used in your pieces? Are there any favorite materials you enjoy working with?

We first tried TotalBoat products at the suggestion of a now friend who works at the local WoodCraft. TotalBoat has changed the quality of our knobs without a doubt. Our knobs are much more clear and have a much harder feel than they did when we first started. We now strictly use TotalBoat products and use them with every single knob we make! When it comes to wood, a lot of people will ask to have a knob that matches their wood steering wheels or trim in their car. If I do not know the type of wood it is, I will reach out to other woodworkers who have been doing it a lot longer than I have and try to find a piece that works perfectly. A lot of the wood we get is from our local WoodCraft. I really enjoy working with black walnut and the TotalBoat ThickSet Epoxy

What challenges do you face when working with epoxy and wood, and how do you overcome them?

The biggest challenge with wood is the moisture content. If the wood has too much moisture or if it dries too quickly there can be cracking. With epoxy, if you don't cast soon enough you are risking bubbles getting trapped. There have been times where we have had to carve out epoxy knobs and recast to fix the bubbles. It is a 50/50 chance for if it will work, but a lot of times the figures we use to create the knobs are irreplaceable so we have had to find ways to make things work when the epoxy doesn't do what we'd like it to do. The pressure pot and humidity level in the garage play a huge part in helping (while also hurting if there is too much humidity) avoid any issues.

Your shift knobs are both functional and artistic—how do you find that balance between practicality and aesthetics?

It really all depends on the size of the knob and how they fit the vehicle. Certain vehicles work with a taller knob that allows for more creativity while some benefit from a much smaller knob. With the metal cores we use, we have to account for space for those to be hidden in the knob. A lot of time, there is research into stock knobs to try and recreate the same general size and shape to make sure it just flows with the vehicle. We then base our creations off that size.

Do you take custom orders, and if so, what’s the most unique or challenging request you’ve received?

We used to take custom orders but stopped taking them last month. When taking custom orders, the most challenging were the sentimental ones (rose from a parent's funeral, special toy someone received from their parent who is no longer here, etc.). These ones are mentally draining as you can do everything right, but you can't control what the resin will do to the item.

What do you think sets Rodak Garage apart from other makers in this space?

Quality. We take pride in making sure each knob has the best quality to date. We are always finding ways to increase quality as to us, nothing is ever perfect and can always be improved on. When looking at our knobs and feeling them, you can just tell the time and pride it took making them.

Do you have any favorite creations or collections that you’ve made? Why do those stand out to you?

Some of my absolute favorite creations are my sea creature knobs. Most of these were created from mess ups to where they are not to the quality I am happy with to sell, but have such a story behind them that makes them unique.

How does the automotive world influence your designs and creations?

I get inspiration from OEM knobs to create different shapes and styles. There are many people who like the shape of a knob they had in one car where that shape isn't in their current car.

How has your business evolved since you first started, and what are some goals you have for the future of Rodak Garage?

Rodak Garage has evolved from being just one person (myself) full time to now having my wife (Donielle) working with me full time. When we first started I had a very limited market with what cars they would fit. This year we have designed a more universal fit for our knobs that allow them to fit into almost any car like stock by creating our own car specific inserts. As time goes on we are planning on creating even more inserts so all of the knobs can fit almost all cars without needing another adapter.

Above: Dave's favorite knob he's made that he finally kept for himself.

What advice would you give to other makers looking to work with epoxy and wood or start their own business?

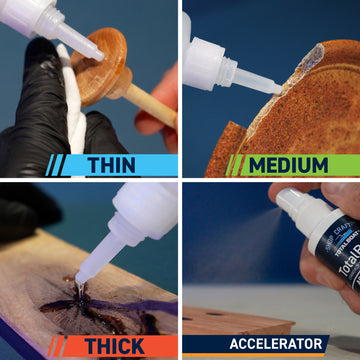

Each epoxy has its own benefits. Experiment with them all and find which ones work best for your projects. We use TotalBoat ThickSet for our single colors and for our clear, TableTop for our clear coat and High Performance for our multicolored bases/knobs. It takes a lot of trial and error to find what works best, but eventually, you get there and it's just the way you want. When it comes to wood, we started with strictly exotic wood and we found that a lot of times it wasn't actually dried correctly so we ran into issues. We eventually came to love working with black walnut and mahogany, which are drastically different from the exotic wood we used to work with. While the exotic wood has some pretty amazing characteristics, even the well known woods have some uniqueness. Try everything and you might just get what you're looking for with the wood you least expect. When starting a business, you have to do honest, quality work and sacrifice a lot to get it going. There are a lot of late nights and a lot of times when you have to put building the business above everything else. It's not an overnight thing, but as long as you keep at it and you are putting your heart into it, you'll eventually get to where you are making it.

What’s next for Rodak Garage? Are there any new projects or products you're excited about?

We don't have any plans for new products at this point, but we are looking forward to creating more long form videos on YouTube and giving more insight into how we create our products!

2 comments

Love the shift knob I’m building a Porsche 914 black on black I think that would be an awesome addition

Well done! Would love a Wolfsburg crest wood and resin shift knob for my Mk7 Golf R :)