Top Picks

Clear High Performance Epoxy Kits

TotalFair Epoxy Fairing Compound

5:1 Traditional Epoxy Resin Kits

ThickSet Deep Pour Epoxy Resin Kits

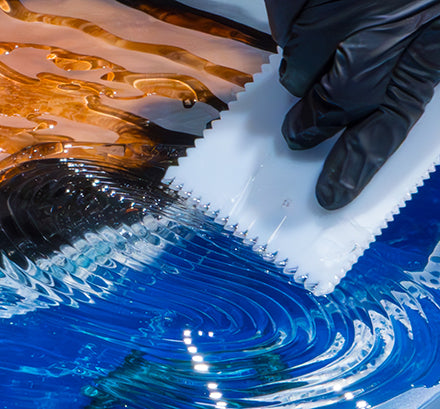

MakerPoxy Crystal Clear Artist’s Resin by Jess Crow

ThickSet Fathom Deep Pour Epoxy Resin

High Performance Epoxy Slow Hardener

High Performance Epoxy Medium Hardener

Clear Epoxy Bar Top & Table Top Project Kits

Epoxy White Marble Effect Countertop Kit

High Performance Epoxy Fast Hardener

Tropical Extra Slow Epoxy Kits

High Performance Epoxy Metering Pump Dispenser

Epoxy Black Marble Effect Countertop Kits

MakerPoxy Metering Pump Dispenser

Kintsugi Epoxy Repair Project Kit

Tropical Extra Slow Epoxy Hardener

TotalBoat

community

Adding UV Protection To Outdoor Epoxy Projects

Zephyr’s Sailboat Countertop Makeover

This Army Vet & Law School Graduate Has A New Calling

Functional Epoxy Art for Fly Fishermen

And the Build Goes On – 15 Boats and Counting

OUR GOAL IS SIMPLE

provide the best tools and inspiration for every craftsperson to succeed.