FULL-SEASON ANTIFOULING PROTECTION

Keeps barnacles and slime off of props, drives, trim tabs, and more - all season.WEARS AWAY GRADUALLY - NO PAINT BUILDUP

Reduces sanding so bottom painting goes faster next season.SAFE FOR UNDERWATER METALS

Copper-free paint won't cause galvanic corrosion on aluminum, steel or iron.EASY TO USE

Apply by brushing, rolling or spraying on prepared aluminum, steel or iron.Outdrive AF Prop and Outdrive Antifouling Paint

Outdrive AF Prop and Outdrive Antifouling Paint

FULL-SEASON ANTIFOULING PROTECTION

Keeps barnacles and slime off of props, drives, trim tabs, and more - all season.WEARS AWAY GRADUALLY - NO PAINT BUILDUP

Reduces sanding so bottom painting goes faster next season.SAFE FOR UNDERWATER METALS

Copper-free paint won't cause galvanic corrosion on aluminum, steel or iron.EASY TO USE

Apply by brushing, rolling or spraying on prepared aluminum, steel or iron.Couldn't load pickup availability

Too many barnacles spoil the prop

Barnacles and slime are not a discriminating lot – they’ll cling to anything. Outdrives and underwater metals need antifouling protection, too. The best time to think about it is before biofilm and hard-shell fouling have formed a crusty green beard on metal parts that help you steer and stay afloat.

Barnacles don’t eat holes in metal like they do in fiberglass and gelcoat, but their bodies block oxygen from the surface. This makes metal rust – even stainless steel, and causes a scary-sounding condition called crevice corrosion. The biocides in Outdrive AF keeps the biofilm from forming, and makes underwater metal surfaces inhospitable to barnacles and other marine fouling organisms.

Copper-free means never having to say you’re sorry to your sterndrive

Do not apply copper-based antifouling paint on underwater aluminum parts, unless you want to watch metals disintegrate from galvanic corrosion. Metal-destroying galvanic corrosion has a few causes, including stray electrical current from other boats in the harbor, or an improperly grounded electrical system on your boat. It also happens when dissimilar metals come in contact with each other underwater.

For example, copper and aluminum are dissimilar metals. They have different electrical potentials, and when in contact with each other, the resulting reaction will cause one of the metals to corrode – in this case, the aluminum. So it’s very important to keep any copper-based antifouling paint used on your hull away from underwater aluminum parts. Outdrive AF is copper-free, so it won’t cause galvanic corrosion. Remember to apply it on your through-hulls, too, because failures caused by galvanic corrosion have sunk many boats right on their moorings.

Very important: Do not paint your zincs and other sacrificial anodes, which are there to keep galvanic corrosion from damaging underwater metals. If you cover them with paint, they won’t be able to do their job, and you’ll get galvanic corrosion anyway.

Full-season protection for boats that stay in the water full-time

Fouling starts the minute you launch your boat. The warmer the conditions, the faster the biofilm grows. Outdrive AF is formulated with biocides and slime-fighting agents that provide protection for a full season for boats that spend most of the season in the water.

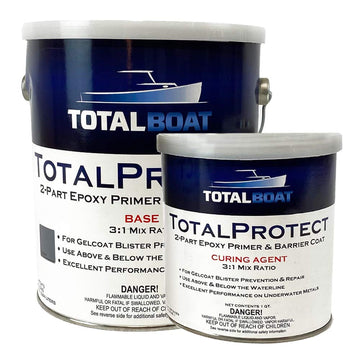

An epoxy primer makes the antifouling paint more effective

Priming reduces surface porosity and gives the antifouling paint a solid surface to adhere to. The paint will stick better and last longer. Aluminum surfaces need to be primed properly. Epoxy primer is recommended because it provides superior adhesion and corrosion protection. For best results, under Outdrive AF paint, prime steel and iron substrates with TotalBoat TotalProtect Epoxy Primer and Barrier Coat. Prep bare aluminum with TotalBoat Aluminum Boat Etch Wash allow to dry, then prime with TotalBoat Aluminum Boat Barrier Coat.

Outdrive AF Antifouling Paint Details

- Use on aluminum and other underwater metals.

- Contains a high concentration of organic, copper-free biocide. Ideal for boatyards under environmental restrictions.

- High-solids, eco-friendly antifouling paint provides outstanding, full-season protection against mussels, barnacles, and slime in salt, fresh, or brackish water.

- Copper-free paint will not cause galvanic corrosion.

- Also prevents hard and soft biofouling effectively on fiberglass and wood, and can be applied over most previously painted surfaces in good condition, including any that contained copper-based paint.

- Ablative formula releases fresh biocide and stays smooth, preventing paint buildup so application is easier next season.

- Color: Black

- Finish: Eggshell

- Size: Quart

- Primer: On all metals except for aluminum, prime with TotalBoat TotalProtect. For aluminum, OR TotalBoat Aluminum Boat Etch Wash and TotalBoat Aluminum Boat Barrier Coat

FREQUENTLY BOUGHT TOGETHER

SEE HOW EASY IT IS TO USE OUTDRIVE AF

SEE HOW EASY IT IS TO USE OUTDRIVE AF

TECHNICAL DATA

- Substrates: Fiberglass, wood, steel/iron, aluminum, and properly prepared previously painted substrates

- Application Method: Brush, Roll (3/16" nap or foam solvent-safe roller cover), or Spray

- Application Temperature/RH: 50-90ºF; relative humidity, 0-90% humidity

- Film Thickness (per Coat): 1.5 mils dry (2.7 mils wet)

- Number of Coats: 1-2

- Dry Time to Overcoat: 1 hour @ 90ºF, 2 hours @ 70ºF, 4 hours @ 50ºF

- Dry Time to Launch: 2 hours @ 90ºF, 4 hours @ 70ºF, 8 hours @ 50ºF

- Color: Black

- Finish: Eggshell

- Seasonal Protection: Single

- Applicable Waters: Salt water & fresh water

- Biocides: Zinc Pyrithione: 4.8% Tralopyril: 6.0%

- Coverage: 100-125 square feet per quart

- Launch Window: There is no maximum dry time before launching.

- Primer: TotalBoat TotalProtect (iron/steel substrates), TotalBoat Aluminum Boat Barrier Coat (aluminum substrates), TotalBoat Aluminum Boat Etch Wash (aluminum substrates)

- Thinner: TotalBoat Special Brushing Thinner 100 (Brush/Rolling), TotalBoat Spray Thinner 101 (Spraying, cool weather Brushing/Rolling)

- Surface Prep Solvent: TotalBoat Dewaxer & Surface Prep or TotalBoat Special Brushing Thinner 100 or TotalBoat Spray Thinner 101

- Cleanup Solvent: TotalBoat Dewaxer & Surface Prep or TotalBoat Special Brushing Thinner 100 or TotalBoat Spray Thinner 101

-

Outdrive AF Prop and Outdrive Antifouling Paint

- Substrates:

- Seasonal protection:

- Applicable waters:

- Colors available:

- Water or solvent based?

- Biocide:

- Application methods:

- Number of coats:

- Primer:

- Thinner:

- Cleanup:

- Coverage:

- Application temperature/RH:

- Units of measure:

- THIS ITEM

-

Outdrive AF Prop and Outdrive Antifouling Paint

- Substrates: Fiberglass, wood, steel/iron, aluminum, and properly prepared previously painted substrates

- Seasonal protection: Single

- Applicable waters: Salt water & fresh water

- Colors available: Black

- Water or solvent based? Solvent

- Biocide: Zinc Pyrithione: 4.8% and Tralopyril: 6.0%

- Application methods: Brush, Roll, or Spray

- Number of coats: 1-2

- Primer: TotalBoat TotalProtect (iron/steel substrates), TotalBoat Aluminum Boat Barrier Coat (aluminum substrates), TotalBoat Aluminum Boat Etch Wash (aluminum substrates)

- Thinner: TotalBoat Special Brushing Thinner 100, for brushing and rolling applications; TotalBoat Spray Thinner 101, for spraying and cool weather brushing/rolling applications

- Cleanup: TotalBoat Dewaxer & Surface Prep or TotalBoat Special Brushing Thinner 100 or TotalBoat Spray Thinner 101

- Coverage: 125 sq ft/qt

- Application temperature/RH: 50-90ºF; 0-90% RH

- Units of measure: Quart

-

Outdrive AF Prop & Outdrive Aerosol Spray

- Underwater metals; properly prepared, previously painted surfaces in good condition

- Single

- Salt water & fresh water

- Black

- Solvent

- Zinc pyrithione: 1.43%

- Aerosol spray

- 2 or more

- TotalBoat Aluminum Boat Barrier Coat (for aluminum); TotalBoat TotalProtect (for all other underwater metals)

- Do not thin.

- TotalBoat Dewaxer & Surface Prep or TotalBoat Special Brushing Thinner 100

- 15 sq. ft. at proper application thickness (1 can per outdrive, with 2-3 coats)

- 40-90°F; 0-90% RH

- 12 oz. aerosol spray can

-

Krypton Copper-Free Antifouling Bottom Paint

- Fiberglass, wood, steel/iron, aluminum, and properly prepared previously painted substrates

- Single

- Salt water & fresh water

- Black, Blue, Green, Red, White

- Solvent

- Zinc Pyrithione: 4.80% and Tralopyril: 6.00%

- Brush, Roll, or Spray

- 1-2

- TotalBoat TotalProtect or TotalBoat Aluminum Boat Barrier Coat

- TotalBoat Special Brushing Thinner 100, for brushing and rolling applications; TotalBoat Spray Thinner 101, for spraying and cool weather brushing/rolling applications

- TotalBoat Dewaxer & Surface Prep or TotalBoat Special Brushing Thinner 100 or TotalBoat Spray Thinner 101

- 500 sq ft/gal, 125 sq ft/qt

- 50-90ºF; 0-90% RH

- Gallons (all colors) and Quarts (Black, Blue, and White only)

-

AlumiPaint AF Aluminum Antifouling Paint

- Aluminum, steel/iron, and properly prepared previously painted substrates

- Single

- Salt water & fresh water

- Black, Blue

- Solvent

- Zinc Pyrithione: 4.8% and Tralopyril: 6.0%

- Brush, Roll, or Spray

- 1-2

- TotalBoat TotalProtect or TotalBoat Aluminum Boat Barrier Coat

- TotalBoat Special Brushing Thinner 100, for brushing and rolling applications; TotalBoat Spray Thinner 101, for spraying and cool weather brushing/rolling applications

- TotalBoat Dewaxer & Surface Prep or TotalBoat Special Brushing Thinner 100 or TotalBoat Spray Thinner 101

- 500 sq ft/gal, 125 sq ft/qt

- 50-90ºF; 0-90% RH

- Gallons and Quarts

YOU MAY ALSO LIKE

FREQUENTLY ASKED QUESTIONS

-

Is Outdrive AF an ablative paint?

Yes. Outdrive AF is a copper-free ablative antifouling paint used on underwater metals. -

What is the best way to apply this paint?

Outdrive AF can be applied by brush, roller, or spray. We recommend using a 3/16" nap or foam solvent-safe roller cover. -

Can it be used on aluminum?

Yes, Outdrive AF is safe to use on aluminum and other metals because it’s copper-free, so it won’t cause galvanic corrosion. -

What thinner is used with this paint?

Outdrive AF should not require thinning, but if desired, use TotalBoat Special Brushing Thinner 100. If spraying, use TotalBoat Spray Thinner 101. -

Can Outdrive AF be used on fiberglass gelcoat?

Yes. While Outdrive AF is specifically formulated for use on underwater metals and aluminum boats, it has excellent adhesion to wood and fiberglass. -

Should I use a clear coat over this paint?

No, it is not recommended to use a clear coat over Outdrive AF, which is a coating designed for application below the waterline. You would lose the antifouling properties by doing so. -

Can this paint be applied over other paints?

Yes, it can be applied on previously painted surfaces in good condition, including any that contain copper, but do not apply it over vinyl or Teflon bottom paints. -

How long will this paint last? How often do I need to apply it?

It offers full single-season protection. You will need to paint every year, like all paints intended for underwater metals. -

Can it be used on a trailered boat?

No, Outdrive AF should not be used on a trailered boat. Refer to Alumipaint AF, Spartan, Krypton, and Underdog for compatible trailered boat bottom paints. -

Does Outdrive AF contain a slime-fighting agent?

Yes! TotalBoat Outdrive AF contains an organic biocide that attacks any build-up of slime and algae growth on your boat hull, propeller, outboard and outdrive. -

Can you paint in the fall and launch in the spring, or does the boat have to be launched immediately?

Yes, you can paint now and launch later without risk of paint losing its antifouling properties. There is no maximum amount of time that the boat can be launched after painting.