EASY DIY PROJECT

Create a faux marble epoxy top that looks like the real thing!ALL-IN-ONE KIT

Project-ready kit has epoxy, tints, tools and directions.TRY SOMETHING NEW

Get great results even if this is your first time using epoxy.EASY TO USE

Step-by-step instructions make it easy!Epoxy White Marble Effect Countertop Kit

Epoxy White Marble Effect Countertop Kit

EASY DIY PROJECT

Create a faux marble epoxy top that looks like the real thing!ALL-IN-ONE KIT

Project-ready kit has epoxy, tints, tools and directions.TRY SOMETHING NEW

Get great results even if this is your first time using epoxy.EASY TO USE

Step-by-step instructions make it easy!Couldn't load pickup availability

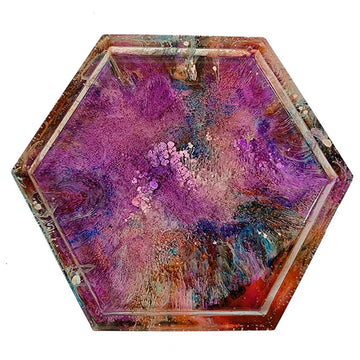

You’ll be pleased and amazed at the beautiful results you’ll get in just 1 day with our TotalBoat TableTop epoxy, a handful of select marbling pigments, and a little attention to timing. Once you learn this simple technique to create the large expanses of white, the gray feathering, and the sinewy black veins that are the distinguishing features of classic white Carrara Italian marble, you’ll want to use it on kitchen islands, bathroom counters, serving trays, and more!

You supply the countertop – it can be a top you’ve fabricated from wood, or a tired old Corian®, Formica®, laminate, ceramic tile, butcher block, cultured marble, or traditional granite countertop that needs a new look.

Available in 4 Kit sizes for small and large projects: 2 Quart Kit, Gallon Kit, 2 Gallon Kit, and 4-Gallon Kit.

Epoxy White Marble Effect Countertop Kit Details

- High-gloss, pourable epoxy

- Simple 1 to 1 mix ratio, by volume

- Self-levels as it cures

- Apply to properly prepared wood, Corian®, Formica®, laminates, ceramic tile, butcher block, cultured marble, and traditional granite surfaces.

- Kit Sizes: TotalBoat Epoxy Marble Effect Countertop Kits are available in a 2-Quart Kit (1 Quart TotalBoat TableTop Epoxy Resin Part A, and 1 Quart TableTop Hardener Part B), a Gallon Kit (1/2 Gallon TableTop Epoxy Resin Part A, and 1/2 Gallon TableTop Hardener Part B), a 2-Gallon Kit (1 Gallon TableTop Epoxy Resin Part A, and 1 Gallon TableTop Hardener Part B), and a 4-Gallon Kit (2 Gallons TableTop Epoxy Resin Part A, and 2 Gallons TableTop Hardener Part B).

Kit Contents

- TotalBoat TableTop Epoxy Resin and Hardener

- TotalBoat Mica Powders – Light Grey, Black Grey, Silver Pearl, 5g/pk

- White liquid opaque pigment (Size: 2 oz.)

- Half-quart plastic mixing cups

- 8 oz. plastic mixing cups

- Large wooden stir sticks (Size: 10")

- Small wooden stir sticks (Size: 5½" x 5/8")

- Chip brushes (Width: 1")

- Epoxy spreaders (Size: 4" x 2-3/4")

- Heat gun with power cord

Not sure how much epoxy you need? Try our simple epoxy calculator to determine how much resin your project will require.

Watch More Videos

-

Turn Wood to Marble! April Wilkerson's Modern End Table

-

Our Tiny Kitchen TRANSFORMATION & TOUR (but actually a Galley ⛵) | EE 63

YOU MAY ALSO LIKE