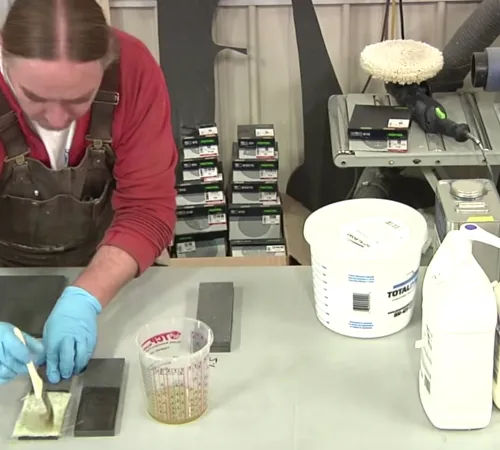

Andy Miller knows a thing or two about resins and boat repair. But when it’s time to reconstruct the transom of the Bertram powerboat he’s restoring, he wants to be certain that he’s using the right resin for the job – and it’s a big, heavy, important job! Andy thought it might be wise to actually see which resins are going to give the best results for both bonding, as well as laminating to the Coosa Board that will be the core of his new transom. This video gives great insight into the differences between Polyester Resin and strengthened vs traditional epoxy resin. Watch and learn from the fiberglass repair pro, Andy Miller and Boatworks Today.