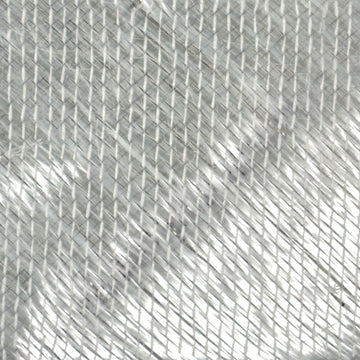

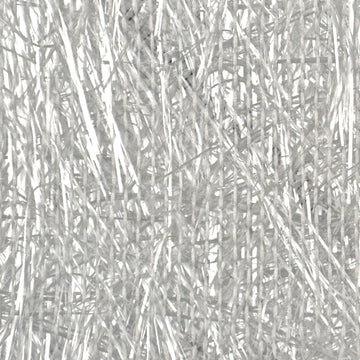

Clever solutions to tricky problems are best shared with our customers so you can get right to your repairs without the guesswork and pitfalls of trial and error. Count on Andy Miller to demonstrate this brilliant method of fiberglass repair that can translate into many solutions for hard to repair areas. Using 1708 fiberglass and our High Performance Epoxy Resin with some milled glass fibers added for super strong adhesion and strength, Andy creates a fiberglass “plate” to install behind the flange he has cut in the stringer. Using screws and some string, he pulls on the installed plate to keep the pressure on the thickened epoxy he has used to set the plate in place. Several more layers of graduated 1708 fiberglass pieces are then applied to the outside, creating a solid stringer wall that will allow Andy to do his next repair there in the way he was hoping to – minus a crooked, half-baked old repair. Tune in and see how Andy makes this Bertram repair like new again!

Holes and large repairs often leave big areas to fill again with fiberglass, and when you’re working on the inside of the hull, finding a way to clamp that repair can be a real challenge. Andy’s screw method is a great solution that starts with a thin lamination of fiberglass and is, once cured, in a great position to be a solid backer for the subsequent layers of fiberglass needed for strength in this important area of the boat.

Andy gives great instruction for tabbing in new glass pieces, making it look easy, and proving that with the right materials and a little video how-to, most anyone can succeed at complicated fiberglass repairs. Check out today’s video of the week with Boatworks Today!