We know you like boats better than river tables and epoxy art. We’re curating our best videos to share with you here, in hopes of showing you some interesting and often times advanced techniques being used by makers, craftsmen and boaters, too. This week we share Part 1 of TotalBoat Ambassador, Paul Jackman’s making of a super-sized Craftsman – er, JACKMAN – clear handled epoxy screwdriver. The process of making this beast has been mesmerizing to witness on Paul’s Instagram feed. We know there’s a great video coming from Paul – but we couldn’t wait to show you the masterpiece in advance of the video launch.

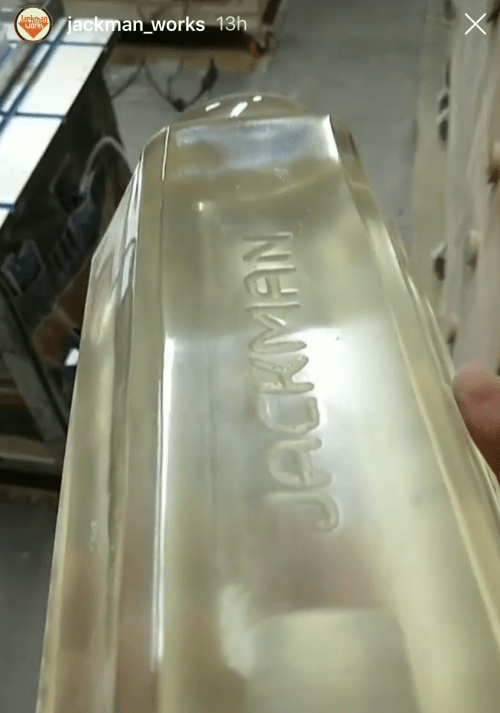

As it turns out, Paul has, unbeknownst to him, employed many boatbuilding techniques in his screwdriver build. The King of Pallet Wood didn’t disappoint when he first made a bunch of glue-ups and chiseled, turned and formed them into a massive Craftsman handle. What appeared to his audience to be an awesome wooden Jackman Sized tool, was really the (here comes the boatbuilding part) plug for the mold he was about to create around his wooden handle. Paul calls it a “form,” and he builds it to his perfect specs, then paints, fills and fairs the part. And that’s when his typical massive wooden tool trick takes a leap! Paul uses a 2-part silicone called Smooth-On to pour into the box he built around the plug. What remains after removing the wooden handle is a perfect mold for him to fill with TotalBoat High-Performance Epoxy.

This filling part raises lots of issues with the depth of Paul’s epoxy pour. Knowing that he has to go in shallow layers to avoid cooking his resin, Paul consults with other makers who suggest he mount the mold box filled with epoxy to his lathe – and turn it. The epoxy cures and pushes to the outside of the form, avoiding any lines showing the different pour depths, and leaving a crystal clear handle for Paul to…. hold.

Paul came to see us at WorkbenchCon maker meetup extraordinaire. He deposited the massive screwdriver into our booth at the show, and the people came to witness the massive piece of…. epoxy… art. Those there knew that the screwdriver, shown above in our booth, was not yet completed. Paul had only temporarily attached the metal piece, and the massive epoxy handle was dull and white, not clear and shiny. The screwdriver was incomplete and awaited a good buff and polish back on his shop lathe. And once that was done – only days ago – suddenly the piece looks nearly perfect – with it’s painted pieces in all the right places (using Elixir paint in Red). It shines, it glows and it’s beautifully clear with no trace of a line or layer to be seen.

As Paul likes to do, he will be releasing a cleverly edited video showing the whole process. He’ll give a step-by-step show of his whole process so that at the end you can go and pour your own massive screwdriver? Ok – maybe not. But we bet you’ll pick up some tips and knowledge from this process that helps you do something better in your own shop.

Share your thoughts, questions, and comments below!